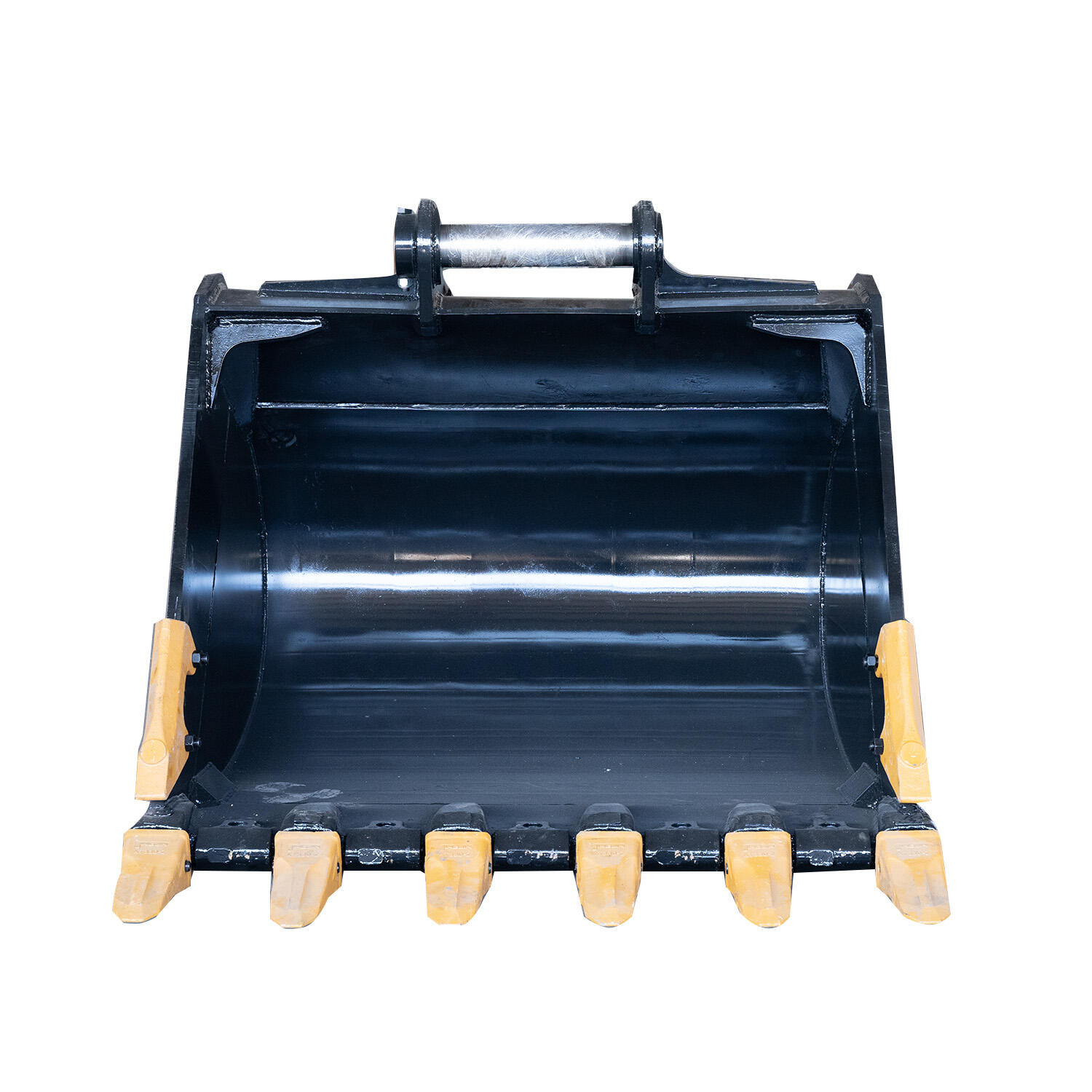

rock teeth for excavator

Rock teeth for excavators are essential components designed to enhance the digging and breaking capabilities of construction equipment. These robust attachments are engineered from high-grade alloy steel, featuring specialized geometry and wear-resistant properties that enable efficient penetration into hard rock and compacted soil. The teeth are strategically designed with replaceable points and adapters that can be easily maintained or switched out when worn, ensuring consistent performance and reducing equipment downtime. Modern rock teeth incorporate advanced metallurgical technologies that provide superior resistance to abrasion and impact, extending their operational lifespan in demanding conditions. These components are precisely manufactured to maintain optimal sharpness and penetration angles, significantly improving the excavator's productivity in rocky terrain. The installation system typically features secure locking mechanisms that prevent tooth loss during operation while allowing for quick replacement when necessary. Available in various sizes and configurations, rock teeth can be matched to specific excavator models and applications, from general construction to specialized mining operations. Their design often includes self-sharpening features that maintain effectiveness throughout the wear life, contributing to sustained performance in challenging environments.