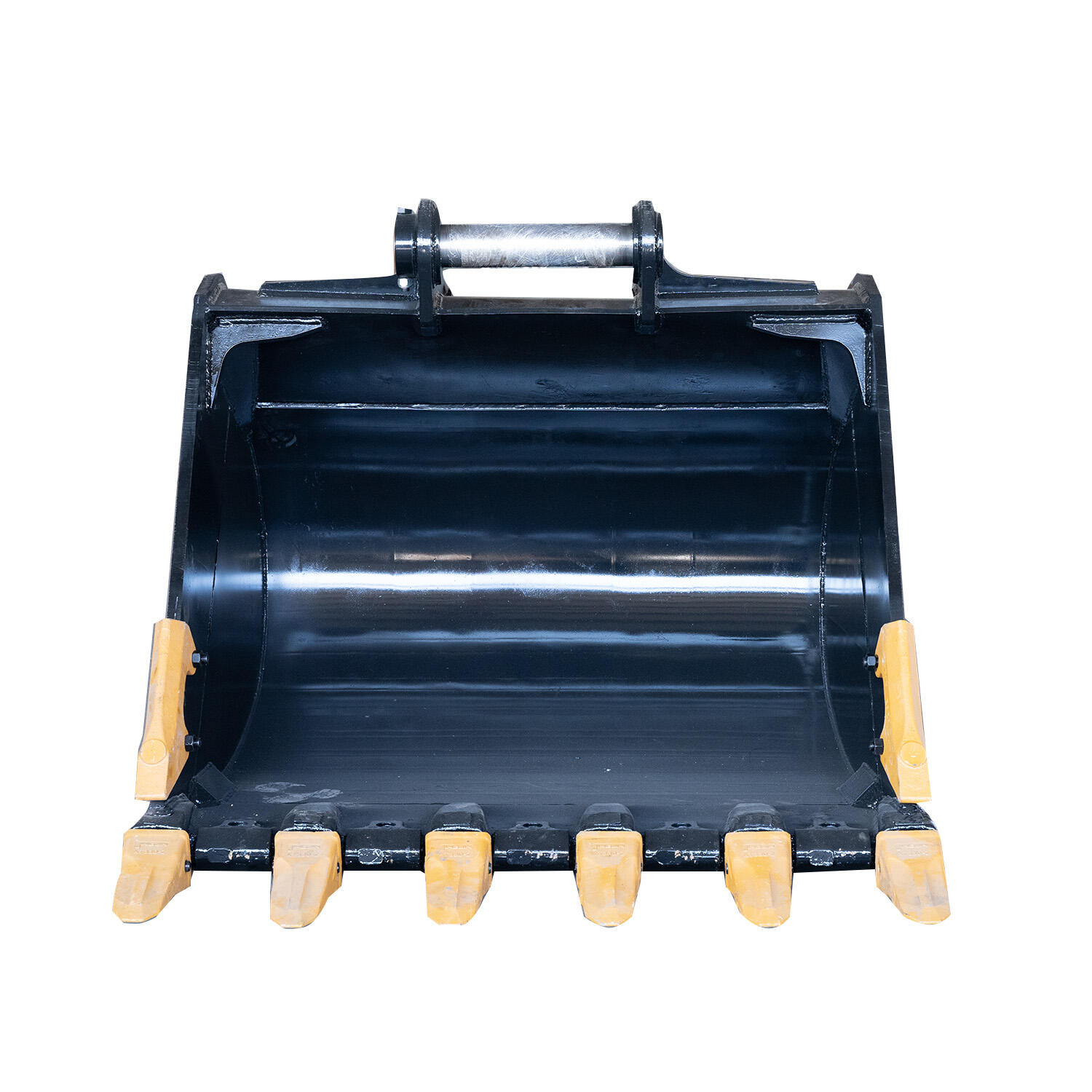

rock teeth for excavator bucket

Rock teeth for excavator buckets are essential components designed to enhance the digging and breaking capabilities of excavation equipment. These robust attachments are engineered from high-strength materials, typically forged steel or alloy metals, to withstand extreme wear and impact during heavy-duty operations. The teeth feature a unique penetrating design that efficiently breaks through hard surfaces, including rocks, frozen ground, and compacted soil. Each tooth is strategically positioned along the bucket's cutting edge to maximize digging efficiency and material penetration. The system includes both the teeth and adapters, creating a secure mounting mechanism that ensures reliable performance while allowing for easy replacement when necessary. Modern rock teeth incorporate advanced wear-resistant technologies and self-sharpening designs that maintain optimal cutting performance throughout their service life. The engineering behind these components focuses on weight distribution and stress management, ensuring balanced operation and reduced strain on the excavator's hydraulic system. These teeth are available in various sizes and configurations to match different bucket types and specific application requirements, from general construction to mining operations.