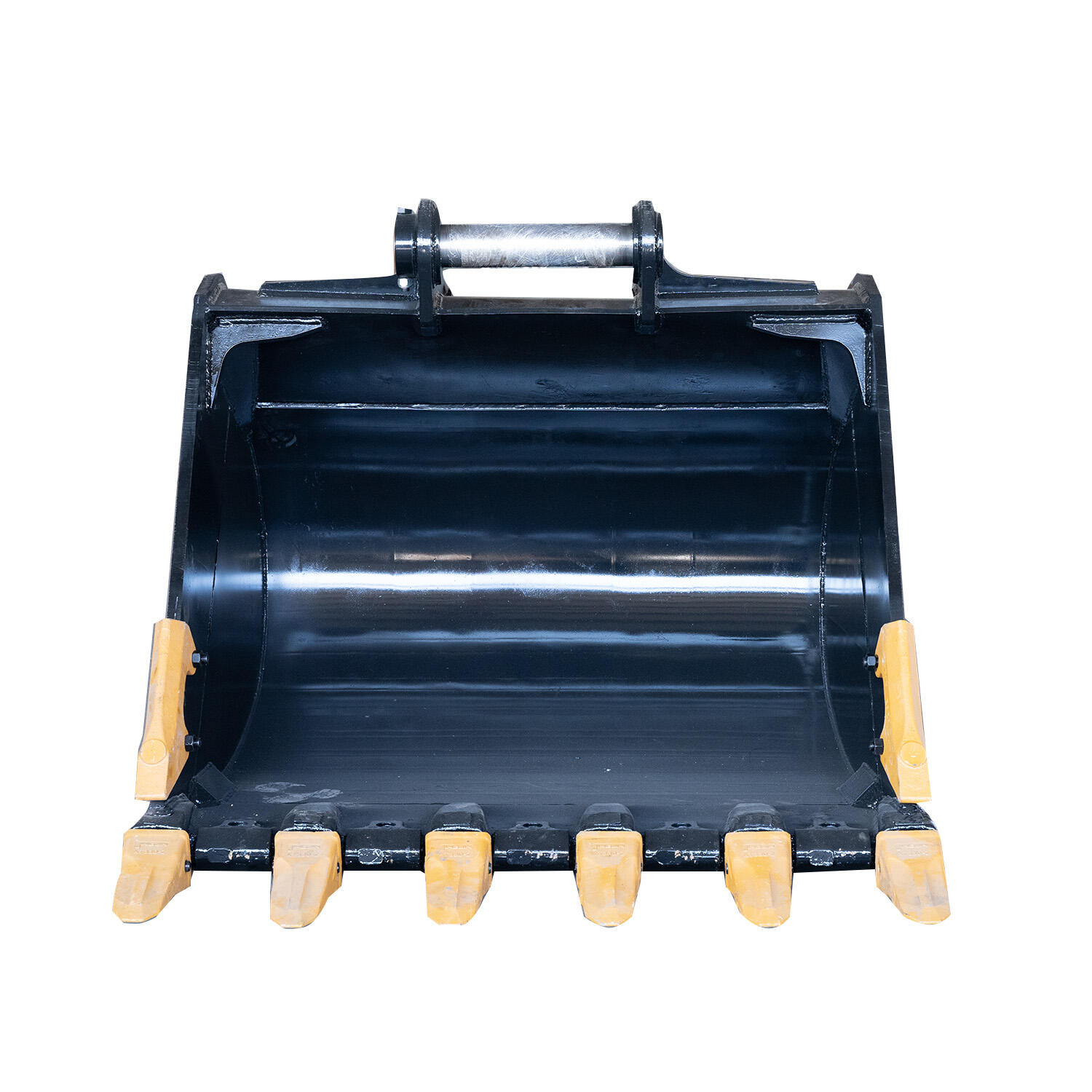

excavator rock crusher bucket

The excavator rock crusher bucket is an innovative attachment designed to transform standard excavators into efficient crushing units. This versatile tool combines the functionality of traditional crushing equipment with the mobility of excavators, enabling on-site crushing and recycling of various materials including concrete, stone, and construction debris. The bucket features hardened steel crushing jaws with adjustable output sizes, typically ranging from 20mm to 120mm, allowing operators to produce precisely sized aggregate materials. The crushing mechanism operates through a powerful hydraulic system that generates the necessary force to break down materials efficiently. Advanced engineering ensures optimal weight distribution and structural integrity, while specialized wear-resistant materials extend the equipment's operational lifespan. The bucket's design incorporates strategic reinforcement points and replaceable wear parts, making maintenance straightforward and cost-effective. Safety features include overflow protection and automatic jaw adjustment systems that prevent damage from oversized materials. This attachment proves particularly valuable in urban construction projects, demolition sites, and areas with limited space for traditional crushing equipment.