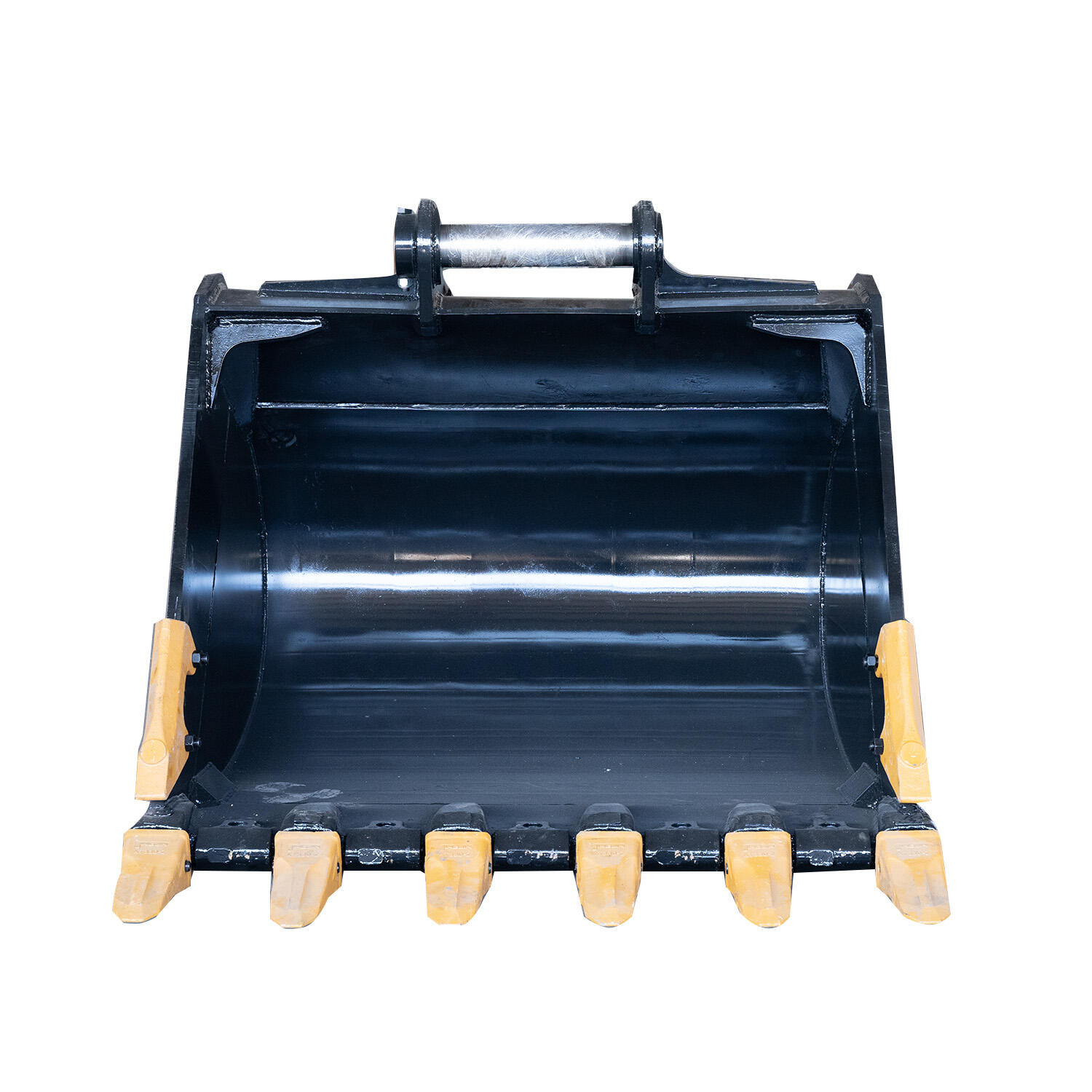

rock excavator bucket

The rock excavator bucket is a robust and versatile attachment designed specifically for heavy-duty excavation work in challenging geological conditions. This specialized equipment features reinforced steel construction with wear-resistant materials, enabling it to effectively break through and handle hard rock formations, consolidated soil, and other demanding materials. The bucket's cutting edge is engineered with high-grade steel and replaceable teeth that penetrate resistant surfaces while maintaining structural integrity during intensive operations. Its unique design incorporates strategic reinforcement points and optimized geometry to maximize breaking force and material handling capacity. The bucket's interior is configured to facilitate efficient material flow and prevent clogging, while its exterior profile ensures optimal penetration angles for various rock types. Advanced manufacturing techniques ensure precise welding and superior durability, making it suitable for extended periods of operation in harsh environments. The rock excavator bucket is compatible with various excavator sizes and models, offering flexibility for different project requirements. This essential tool finds applications in mining operations, quarrying, construction sites, and infrastructure development projects where dealing with hard rock material is a primary concern.