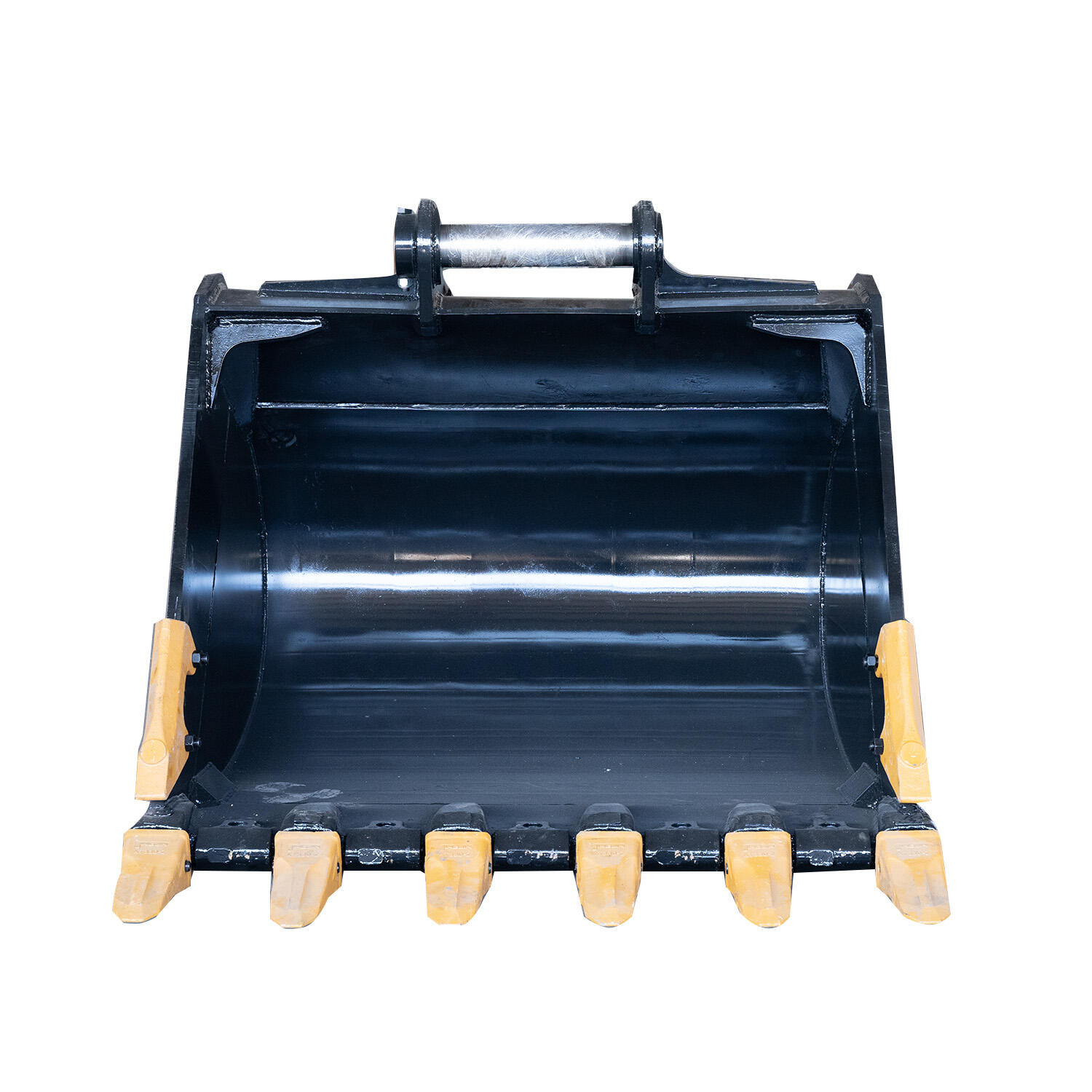

mini excavator skeleton bucket

The mini excavator skeleton bucket is an innovative attachment designed for compact excavators, offering exceptional versatility in material handling and sorting operations. This specialized bucket features an open design with parallel bars or tines, allowing operators to effectively separate materials while retaining larger items. The skeleton bucket's unique construction enables efficient screening of soil, debris, and other materials directly on-site, eliminating the need for separate screening equipment. Its robust construction typically incorporates high-grade steel components, ensuring durability in demanding conditions while maintaining optimal weight characteristics for mini excavators. The bucket's design facilitates improved visibility during operation, enabling operators to monitor material processing more effectively. With various width options and tine spacing configurations available, these buckets can be customized to match specific project requirements. The skeleton bucket proves particularly valuable in landscaping, construction waste management, and agricultural applications, where material separation is crucial. Its ability to handle diverse materials, from topsoil and compost to construction debris and agricultural waste, makes it an indispensable tool for contractors and operators seeking to enhance their operational efficiency.