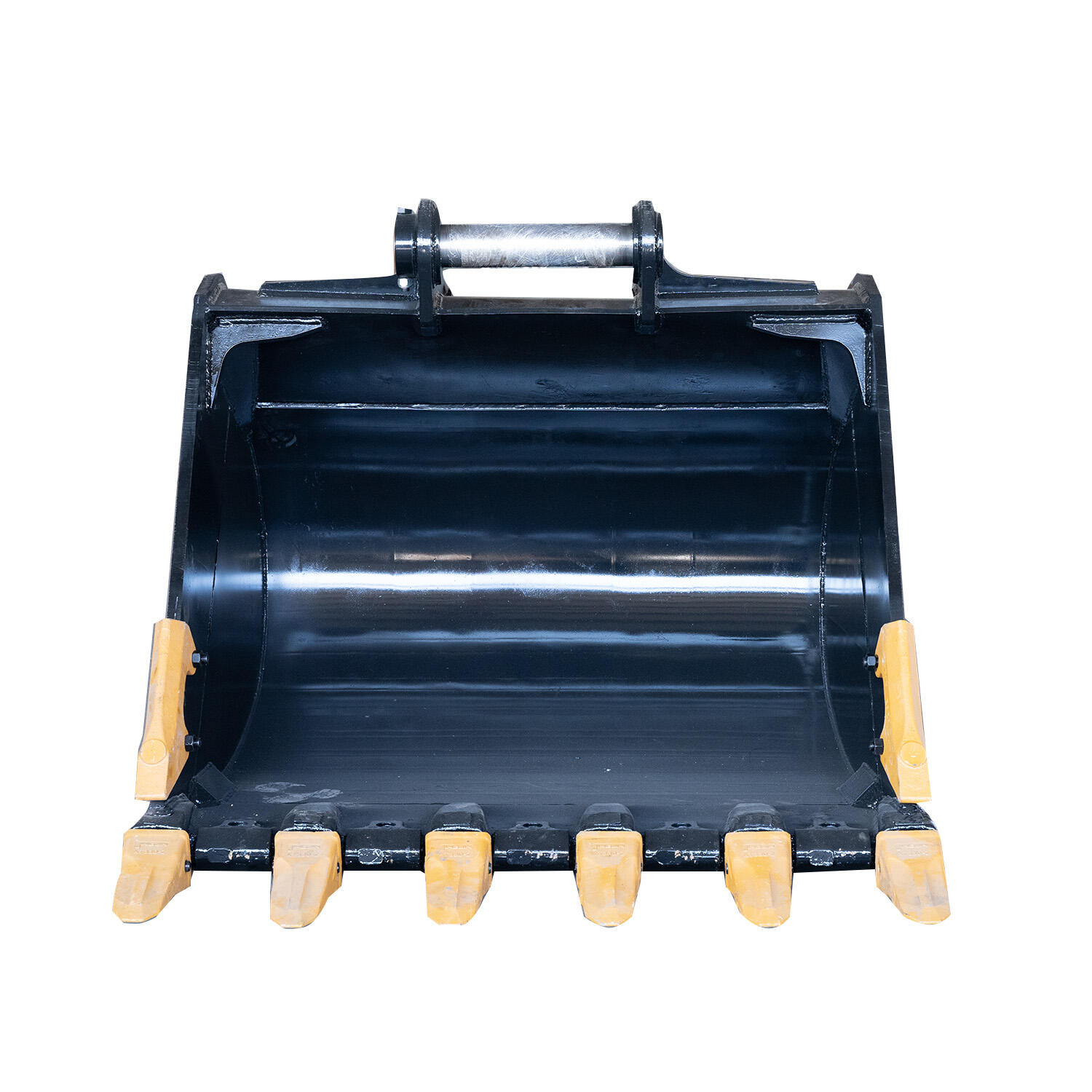

rock teeth for mini excavator

Rock teeth for mini excavators are essential attachments designed to enhance the digging and breaking capabilities of compact construction equipment. These specialized components are engineered with high-strength materials, typically hardened steel or carbide-tipped alloys, to withstand intense pressure and abrasion during excavation work. The teeth feature a unique geometric design that optimizes penetration force while maintaining structural integrity under heavy loads. They are specifically sized and shaped to complement mini excavators' compact nature while delivering maximum efficiency in challenging terrain. The teeth's innovative design includes a self-sharpening capability that maintains cutting effectiveness throughout their operational life. Installation systems are typically designed for quick replacement, featuring secure locking mechanisms that prevent unexpected detachment during operation. These components are crucial for various applications, including rock breaking, demolition work, foundation preparation, and general excavation in hard soil conditions. The teeth's durability is enhanced through heat treatment processes that create a harder exterior while maintaining a somewhat ductile core, preventing brittle failure under impact. This sophisticated balance of hardness and toughness ensures reliable performance in diverse working conditions, from frozen ground to solid rock formations. Modern rock teeth also incorporate wear indicators that help operators monitor replacement timing, optimizing maintenance schedules and reducing downtime.