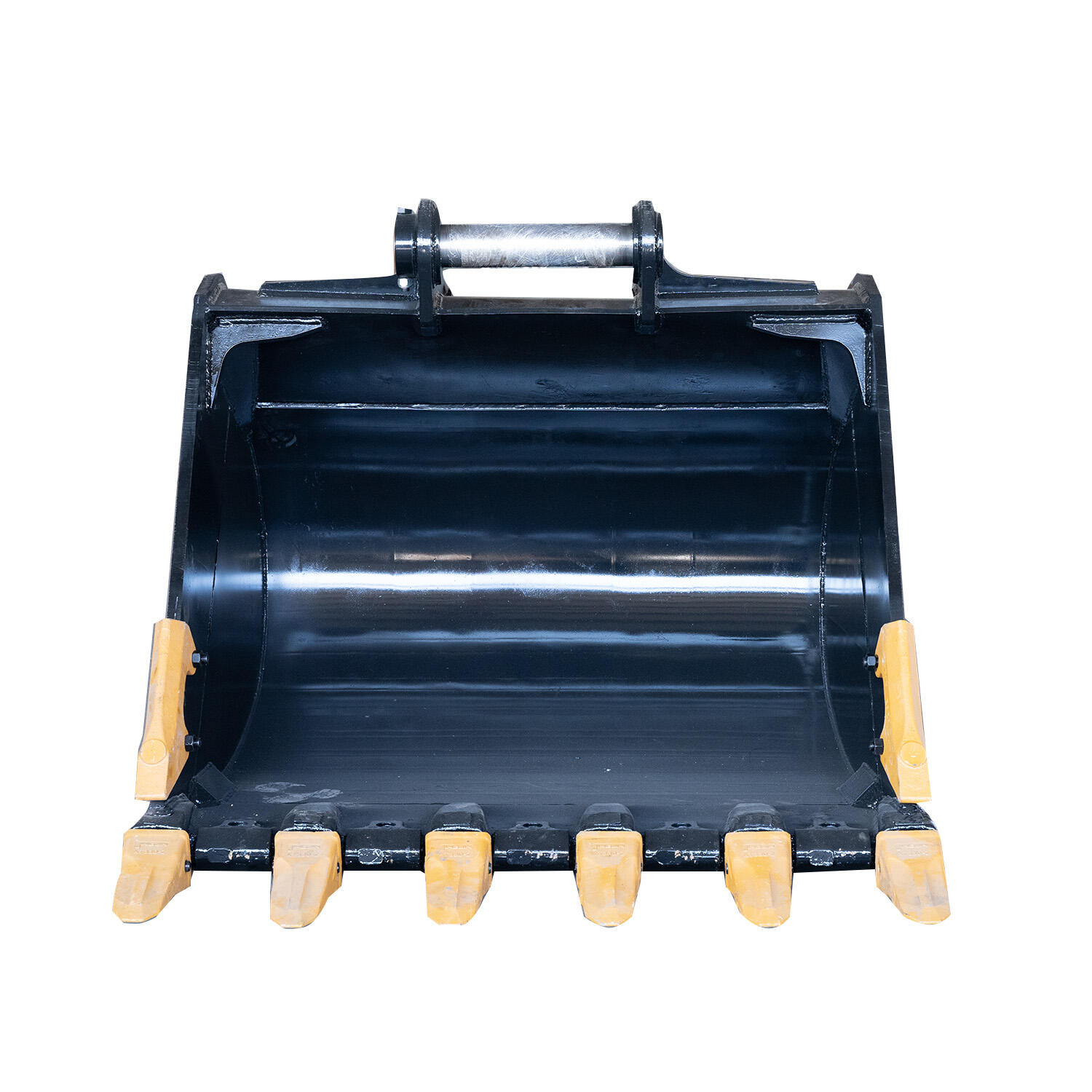

skeleton bucket for excavator for sale

The skeleton bucket for excavator represents a specialized attachment designed for efficient material separation and sorting operations. This innovative tool features a unique grid-like structure with strategically spaced bars that allow smaller materials to pass through while retaining larger objects. Engineered with high-strength steel, these buckets offer exceptional durability and wear resistance, making them ideal for demanding construction and recycling applications. The design incorporates reinforced side plates and wear strips to ensure longevity, while the optimized spacing between bars maximizes screening efficiency. Available in various sizes to fit different excavator classes, these skeleton buckets are particularly effective in applications such as soil screening, construction waste sorting, rock separation, and compost processing. The bucket's structure enables operators to separate materials on-site, significantly reducing transportation costs and improving workflow efficiency. Advanced manufacturing techniques ensure precise bar spacing and optimal structural integrity, while the bucket's geometry is calculated to maintain proper material flow and prevent clogging. Additionally, many models feature replaceable wear parts to extend service life and reduce maintenance costs.