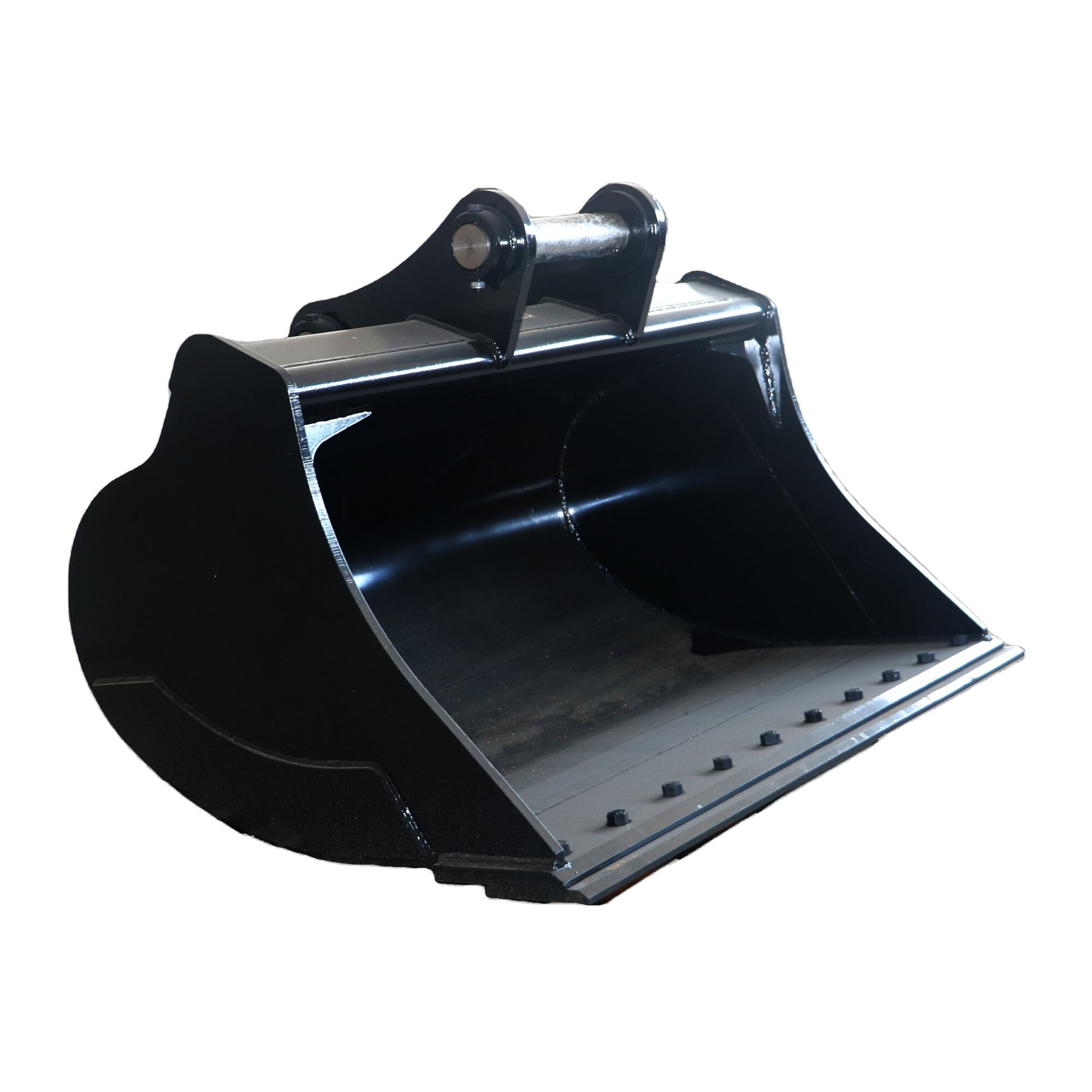

manual thumb for excavator

The manual thumb for excavator is a versatile attachment that revolutionizes the capability of standard excavators, enabling them to grasp, lift, and manipulate objects with precision. This mechanical device consists of a robust steel framework that attaches to the excavator's stick, working in tandem with the bucket to create a claw-like gripping mechanism. The manual thumb operates through a straightforward pin-and-plate system, allowing operators to adjust the thumb's position manually for different tasks. Its design incorporates high-grade steel construction with reinforced pivot points to ensure durability under heavy-duty applications. The manual thumb's functionality extends across various construction and demolition tasks, from clearing debris and handling logs to positioning rocks and managing construction materials. Its adjustable positions typically range from 0 to 120 degrees, providing flexibility for different material sizes and shapes. The attachment's simplicity in design translates to minimal maintenance requirements while maintaining reliable performance in challenging conditions. Modern manual thumbs often feature wear-resistant surfaces and optimized tooth patterns that enhance gripping capability and extend service life.