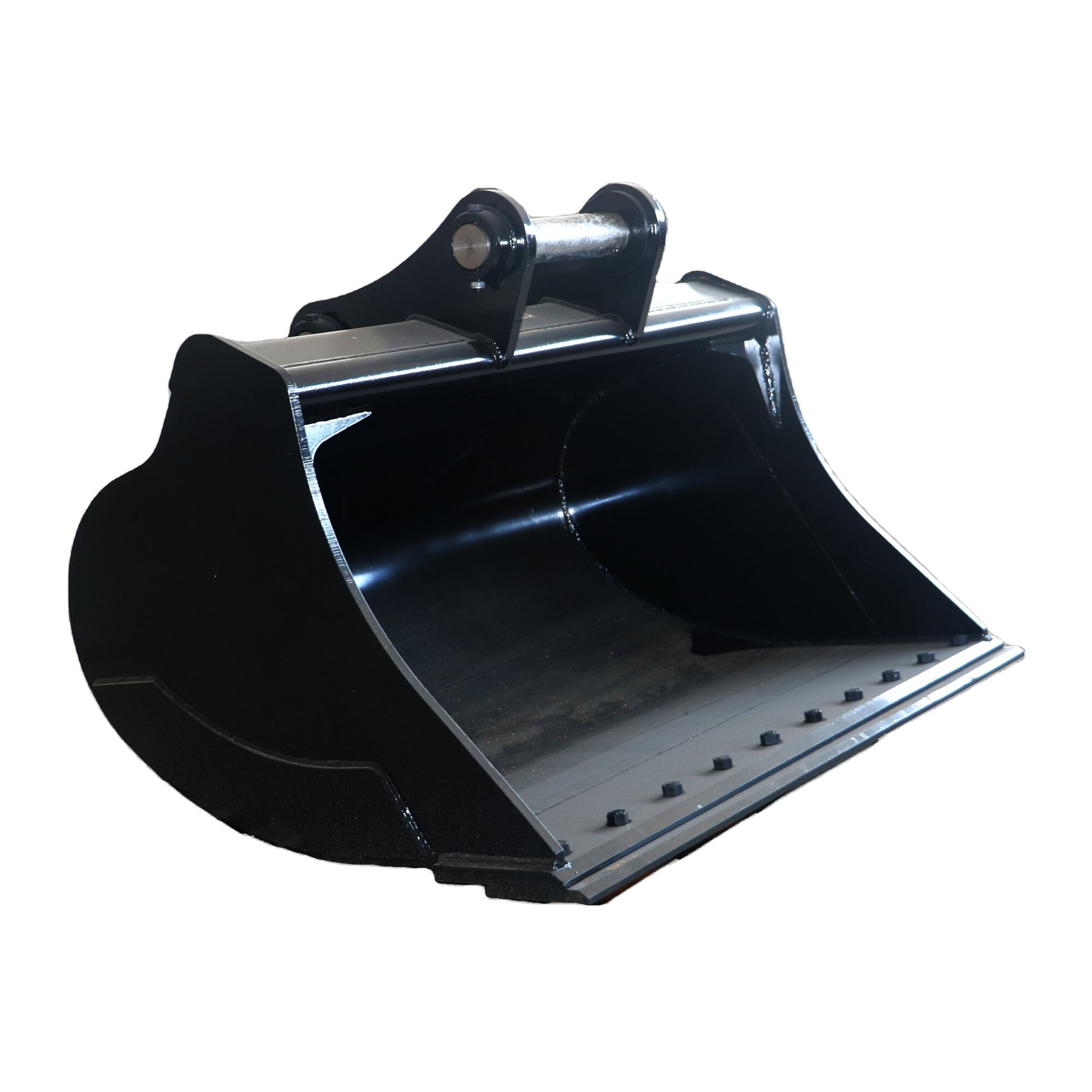

excavator thumb

An excavator thumb is a versatile attachment that revolutionizes the capabilities of standard excavator machines. This mechanical or hydraulic device attaches to the excavator's stick and bucket, creating a claw-like mechanism that significantly enhances the machine's gripping and material handling abilities. The thumb works in conjunction with the bucket, operating like a human thumb and forefinger to grasp, sort, and manipulate various materials with precision. Modern excavator thumbs feature robust steel construction, designed to withstand heavy-duty applications and harsh working conditions. They come in various styles, including progressive link, fixed, and hydraulic models, each offering specific advantages for different applications. The attachment's design allows for efficient handling of irregular objects, debris removal, land clearing, and demolition work. The hydraulic versions offer superior control and flexibility, enabling operators to adjust the thumb's position independently of the bucket. This attachment has become indispensable in construction, demolition, landscaping, and waste management industries, significantly improving productivity and expanding the range of tasks a single excavator can accomplish. The technology behind excavator thumbs continues to evolve, with manufacturers incorporating advanced materials and engineering solutions to enhance durability, operation smoothness, and overall performance.